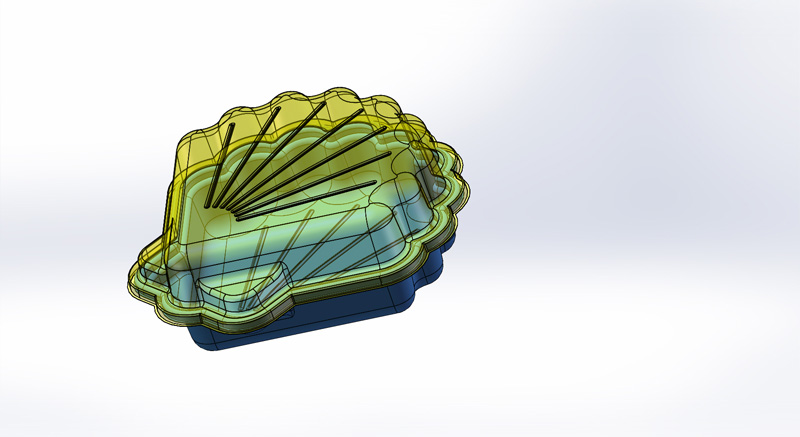

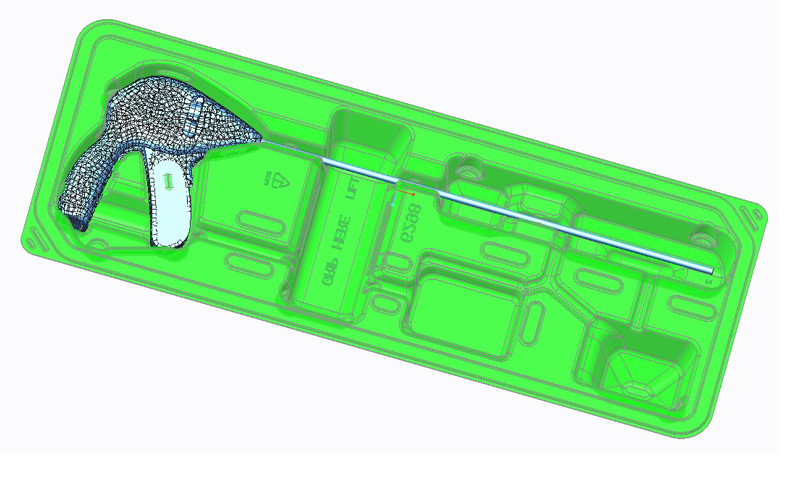

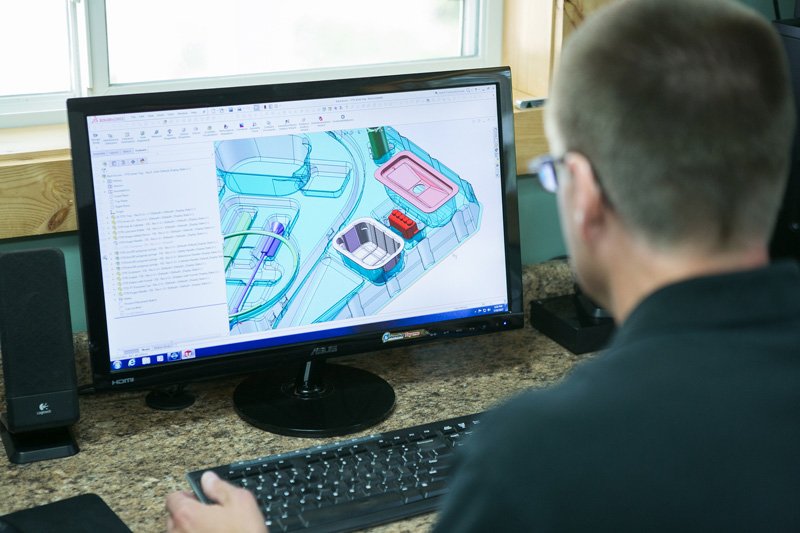

We are not just designers, we are engineers, so we incorporate technical knowledge into creative ideas. Our team uses a common sense approach to product design. Regardless of a part’s stage in development, we consult with you to get a 360 degree understanding of your vision. We analyze function, features, manufacturing process, and distribution. Our team can then create a 3D model in CAD. Early in the design stage, we identify and eliminate problem areas, examine or change a part design, and reduce costs that are associated with traditional trial and error methods. From there, we collaborate with you and our engineers through concept creation and product finalization.

Our official

thermoforming

design process includes

- Concept development

- Finalized 3D part development

- Finalized part specification documentation

- Client-owned electronic databases

THE DESIGN PROCESS

From concept to creation.